Advantages of Revolutionary Silicon Carbide Ceramic Membranes

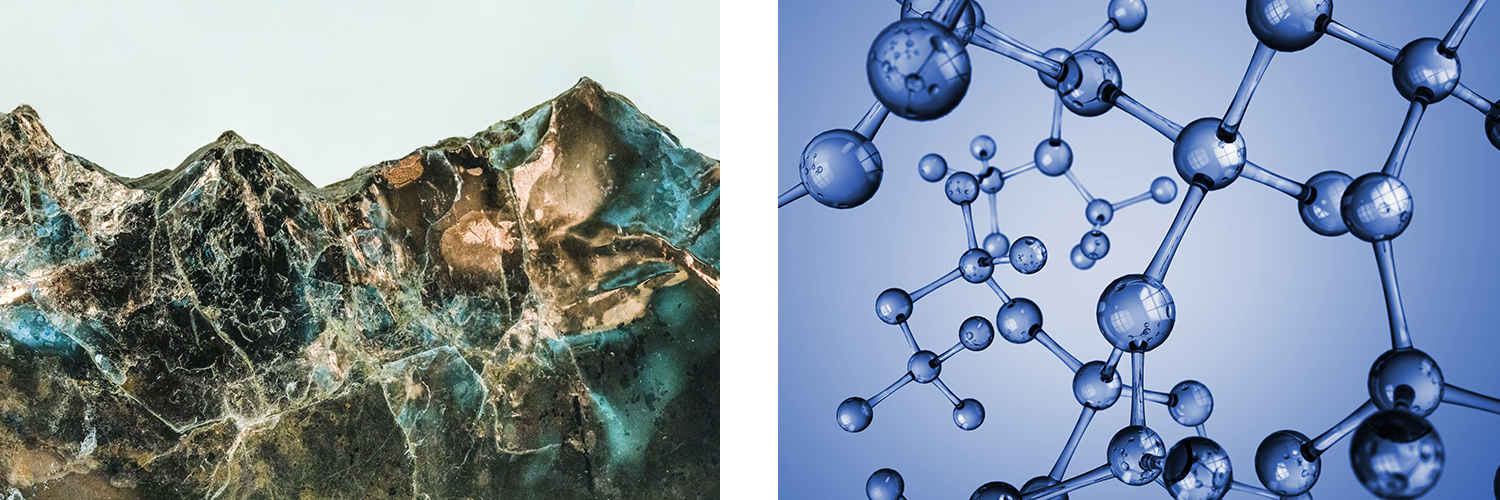

Has been producing recrystallized silicon carbide products for over two decades, providing state-of-the-art silicon carbide ceramic membrane products for gas and liquid purification. We specialize in two business areas: Silicon Carbide Ceramic Membranes for liquid filtration and Diesel Particulate Filters (DPFs) for controlling soot emissions from diesel engines. Utilizing nanotechnology, we develop patented products utilizing patented silicon carbide technology. Our products are based on unique silicon carbide ceramic membranes that facilitate new applications and improve existing technologies.

Our diesel exhaust and liquid filtration products use silicon carbide ceramic membranes, which we believe have certain qualities that make our products more effective than our competitors. Unlike filtration products that use alumina, silicon carbide membranes are chemically inert and temperature resistant. Furthermore, SiC ceramic membranes exhibit a high degree of hydrophilicity (tendency of the surface to become wet or absorb water), resulting in a unique flux (low energy consumption). Silicon carbide is also extremely durable, second only to diamond in hardness, making it an ideal material for a variety of corrosive liquids in industrial applications. Therefore, we believe that this superior physical property makes our products ideal in both exhaust emission control products and liquid filtration products.