We are here to remove unburned fuel oil, soot particles, ash, and heavy metals from marine scrubber wastewater and take an active role in reducing world pollution. We care about the future, and at the same time, about growth. We see it as our mission to enable marine companies to grow stronger while meeting tomorrow's environmental demands. That means the world to us.

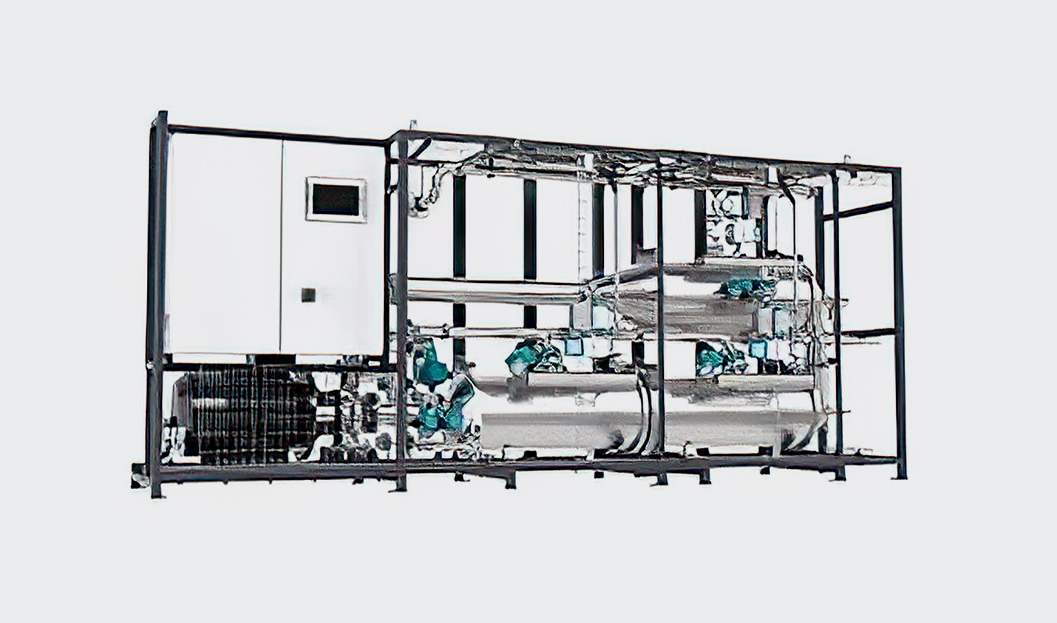

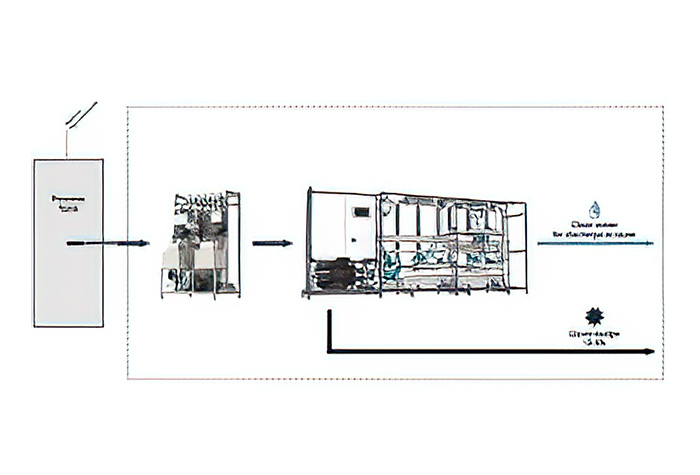

LiqTech offers complete wastewater treatment solutions consisting of:

● Coarse pre-filtration ● Fully automated SiC membrane system ● Module for dewatering of membrane reject

LiqTech has developed a compact and efficient marine scrubber water treatment system for both closed-loop and hybrid scrubbers that outperforms discharge limits regulated by the IMO. Working with market leaders for several years, we have successfully installed retrofit and new-build marine scrubber water treatment systems on hundreds of vessels.

● 12-18 month ROI ● Continuous operation on fossil fuels in SECAs (IMO) ● Ideal for retrofit installation ● Future-proof solution ● Selected by market leaders ● Guaranteed compliance with IMO discharge regulations ● Market leader with +250 systems in operation